The Down and Dirty:

Biodegradable Hydraulic Oil

and Plant-Based Grease

WHY BIODEGRADABLE OILS AND PLANT-BASED GREASES

MATTER ON EARTH DAY AND BEYOND

Earth Day is a yearly reminder to look at what each of us is doing to sustain the planet. For some businesses, that means recycling or adopting energy-saving systems like solar or LED. In the fluid, oil, and grease industry, the push to find eco-friendlier solutions in the form of bio-based products matters year-round, driven not only by a desire to be more environmentally conscious but also by price volatility and supply challenges.

Thankfully, bio-based lubricants have improved through the years and are becoming more popular. Read on to learn about what makes them special, how they are environmentally friendlier, and why you might choose one for your business.

What Makes Bio-Based Oil and Grease Special?

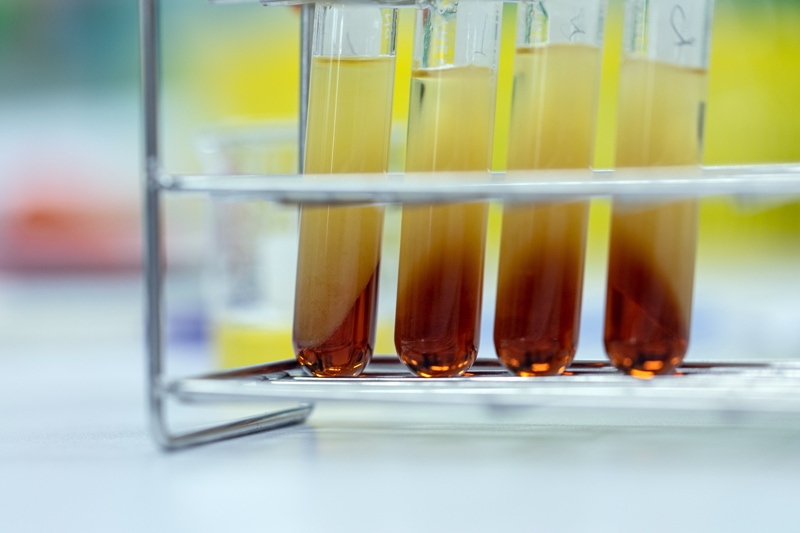

Bio-based oil and grease are different because instead of having a petroleum or mineral oil base, they are made from plant and vegetable oils. These oils include corn, soybean, rapeseed (canola), sunflower, peanut, and chemically synthesized esters. Soy and canola are used most often for industrial lubricants, and these bases feature outstanding lubricity (slipperiness) and can have higher flash points. Synthetic esters deliver a more biodegradable formulation than conventional mineral oils, and can have an extended service life.

One of the key advantages of bio-based oils is that, unlike traditional crude-based oils and greases, the ability to produce more supply from a renewable source is nearly limitless. In addition, plant-based oils can create partnerships: For example, using lubricants and greases made of soybean oil helps reduce soybean surpluses and helps stabilize soy prices for American farmers.

What Are the Main Types of Bio-Based Lubricants?

- Biodegradable Hydraulic Oil

Right now, bio-based hydraulic oil is the most well-known option that is used across industries. As technology advances, there will likely be more biodegradable lubricants on the market, from gear lubricants to compressor oils and transmission cooling fluids.

A few industries with successful uses of biodegradable oils are mobile hydraulic systems, marine, and forestry. New advances toward drill oils and bar and chain oils are seeing more market share as well.

- Plant-Based Grease

How Are Bio-Based Lubricants Environmentally Friendlier?

- Biodegradability

- Minimal toxicity

- Non bio-accumulating

- Effectiveness

Let’s break down each standard.

- Biodegradable

- Readily biodegradable means that within 28 days, 60% of the lubricant has biodegraded.

- Inherently biodegradable – means that within 28 days, at least 20% of the lubricant has degraded.

- Minimal Toxicity

- Non Bio-Accumulating

- Effectiveness

Why Would You Choose a Bio-Based Lubricant?

Bio-based hydraulic oils have improved through the years to match mineral oil based lubricants in many ways while being kinder on the environment. Here are reasons:

- Environmental concerns: When you have a specific application that involves a risk of environmental exposure to oil leakage, biodegradable lubricants are a smart choice. For example, biodegradable hydraulic fluid has the benefit of less environmental impact if the fluid breaches containment. In the offshore oil and gas and marine sectors, where equipment and vessels have the potential to leak oil into the marine environment, there is a growing global trend to use biodegradable lubricants.

- Legislation requirements: Rules in the United States and Europe require bio-based lubricants for certain uses or locations. In the U.S., specifically around bodies of water and waterways, use of biodegradable lubricants are required by federal and state laws. The EPA and U.S. Department of Agriculture (USDA) have outlined strict requirements pertaining to the usage of biodegradable lubricant products. In European Union countries, companies must use lubricants that comply with an ECOLABEL specification in defined sensitive zones.

- Performance properties: With advances in technology, many bio-based oils and greases now have performance comparable to conventional and fire-resistant mineral greases. For example, hydraulic oils for use in mobile equipment can be made from a blend of synthetic diester and canola oil to deliver excellent temperature viscosity properties and good oxidation stability, even in colder operating conditions.

- Supply opportunities: Because bio-based oils and greases come from renewable sources (plant and vegetable seeds), they have an advantage over petroleum bases in terms of sourcing. Vegetable oils tend to receive more focus during wartime and oil shortage situations. For example, during World War I and World War II, the use of vegetable oils for fuel, lubricants, and greases rapidly increased. Also, the oil embargo of 1973 brought attention to alternatives for petroleum oils. It’s possible that current events unfolding in Russia and Ukraine now will also drive more interest in other bio-based oils today.

Whether conventional petroleum or bio-based, Pack Logix offers a range of filling options for all types of lubricants, plus fluid and solvents. Reach out today to learn how our experts can serve your business.