The True Cost of Quality and

Hidden Costs of Rework

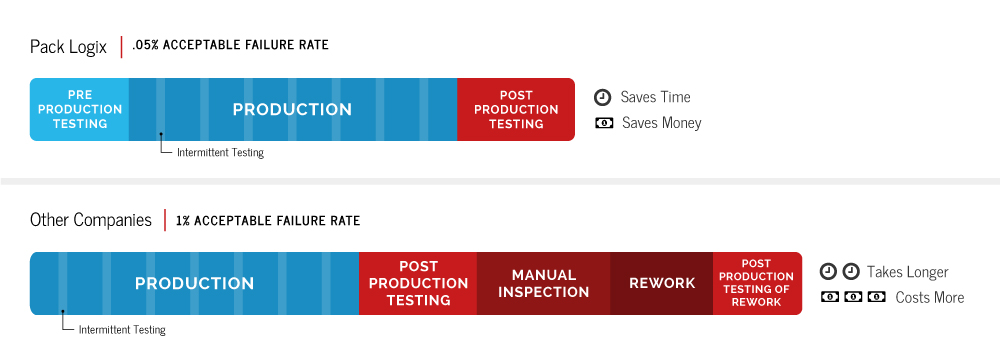

At Pack Logix, our commitment to quality isn’t just a value statement; it’s a strategic investment that underpins our entire operation. To us, maintaining the highest quality standards is a non-negotiable, requiring a proactive approach before your product even hits the production line.

Our proactive approach is rare in our industry. Many lubricant and chemical contract packagers focus solely on end-of-the-line post-production issues, which impact your product’s quality and cost. Read on to learn more about the true cost of quality and the hidden costs of rework.

What is the True Cost of Quality?

However, the true cost of quality goes beyond just monetary value. It reflects our commitment to excellence and our dedication to our customers. Ensuring quality from the outset means fewer disruptions, less waste, and more satisfied customers. Our comprehensive quality control processes include frequent checks every five minutes, covering seal quality, bottle cleanliness, date code stamps, label application, and weight. Additionally, a dedicated quality inspector performs random checks throughout the day to further ensure consistency.

The Hidden Costs of Rework

- Segregation of Pallets

- Manual Inspection

- Increased Labor Costs

- Human Error Risk

Overall Cost Impact

Getting It Right the First Time

At Pack Logix, we understand that the best way to manage the cost of quality is to prevent defects before they occur. This proactive approach is more cost-effective and efficient than dealing with the hidden costs of rework. By investing in rigorous quality control measures and maintaining high standards throughout the production process, we minimize the need for rework and ensure that our products meet or exceed customer expectations.

At Pack Logix, we are committed to getting it right the first time, every time, to avoid the hidden costs of rework and ensure the highest level of quality for our clients.